Durability & Reliability Solutions

_

Validate strength and lifetime with confidence.

Durability and reliability testing uses multi-axis rigs, durability shakers, and advanced software to simulate years of fatigue, helping OEMs ensure long-term performance.

What Problems We Solve?

- Fatigue failures during field operation

- Warranty issues from insufficient durability

- Poor correlation between simulation and physical testing

- Unverified service life for critical components

Why Choose Us?

- Accelerated lifecycle testing condenses years into weeks

- Siemens durability analytics integrated into test workflows

- Component and system-level fatigue rigs (hydraulic and electrodynamic)

- Trusted by automotive, aerospace, and defense industries

Our Solutions Include

_

Simcenter durability testing solution

Suite for fatigue analysis, durability assessment, and lifetime prediction

Siemens Simcenter SCADAS Mobile

Portable multi-channel DAQ for lab and in-vehicle NVH tests, delivering high-fidelity signals and tight Testlab integration

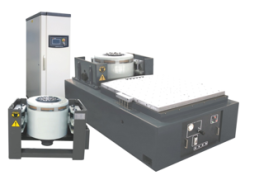

Dongling Electrodynamic Shakers

High-force shakers for fatigue and vibration testing.

Stresstech Barkhausen Noise Analyzers

Systems for detecting surface flaws and residual stresses