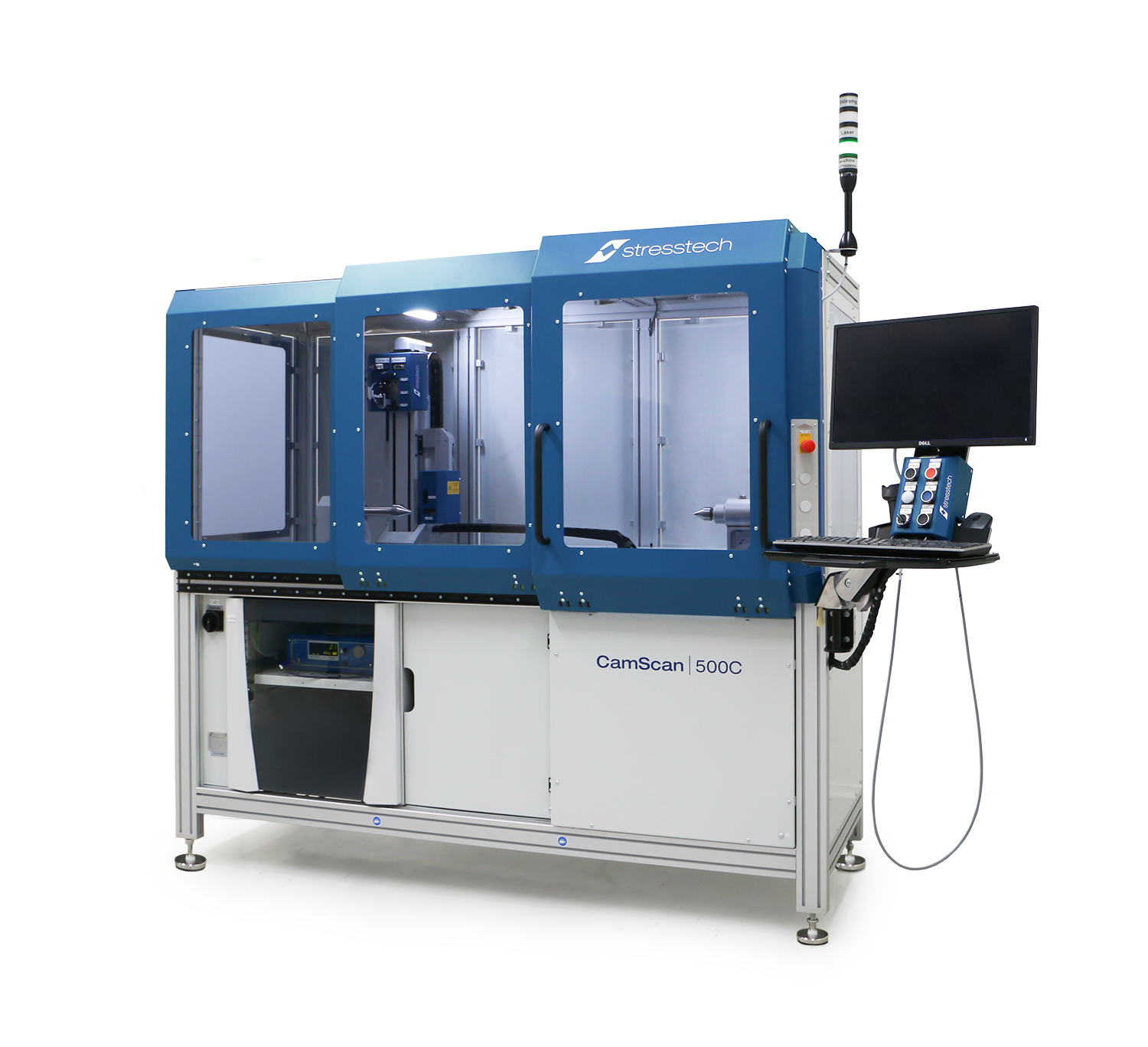

Barkhausen Noise Equipment

Non-destructive (NDT) measurement solutions for grinding burn and heat treatment defect testing.

Stresstech’s Barkhausen Noise Inspection systems offer a reliable, non-destructive way to detect grinding burns, heat treatment defects, and surface stress variations.

By analysing the magnetic noise generated from a magnetised surface, the systems reveal subtle microstructural changes that affect component quality.

Each system is modular and can be configured with the Rollscan signal analyser, Barkhausen noise sensors, and ViewScan or MicroScan software, available in manual, semi-automated, or fully automated setups to fit different production needs.

System Levels & Inspection Families

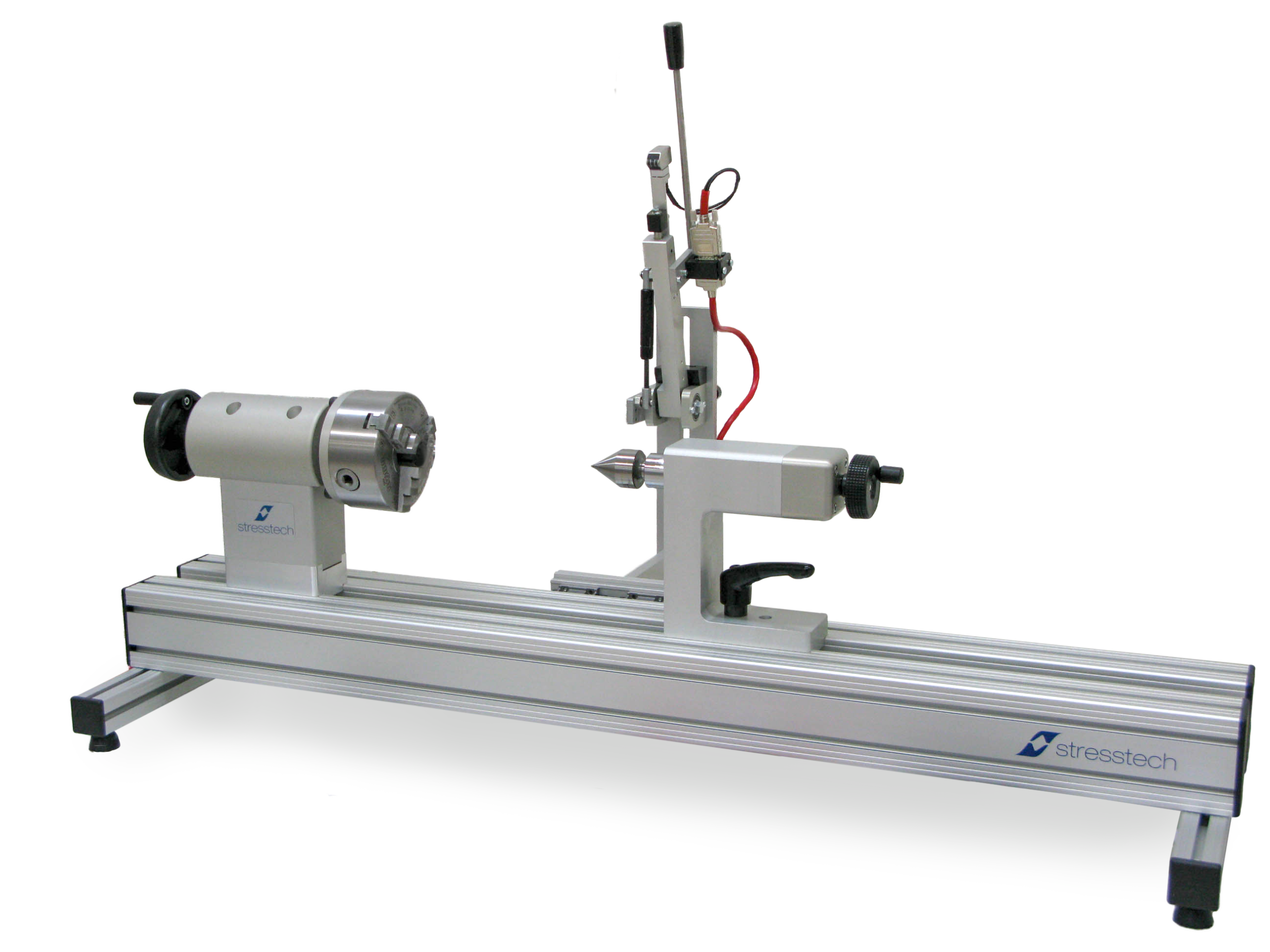

Stresstech offers Barkhausen noise inspection systems designed for a wide range of steel components.

The systems are available in several automation levels to match different production requirements from manual setups ideal for laboratories and R&D, to semi-automated and fully automated inline solutions used in high-volume manufacturing.

Signal Analyzers

Stresstech’s Rollscan signal analysers are the core measurement units used in Barkhausen noise inspection. They provide high‑quality data for detecting grinding burns, heat treatment defects and changes in stress and microstructure on ferromagnetic components.

To meet different application needs, Stresstech offers three main models of Barkhausen noise analyzers:

- Rollscan 350: the newest generation offering adjustable measurement parameters via an on‑board graphical interface (no PC required). It provides oscilloscope display with sensor feedback, supports multiple languages and advanced connectivity options.

- Rollscan 250: a portable yet full‑featured unit designed for laboratory, in‑line and on‑site use. It has a LED display, two measurement channels and a robust design.

- Rollscan 320: a compact analyser with low power consumption, ideal for automated systems. It mounts on a DIN rail and can integrate up to eight parallel analyzers (16 channels).

Each model combines precision measurement with ease of use, ensuring consistent and dependable results in every inspection.

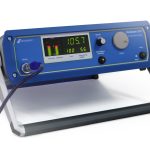

Rollscan 250 is a full-featured, self-contained unit which is portable for on-site measurements while also providing advanced capabilities for in-line and laboratory use.

- Led display with sensor feedback for real-time measurement diagnostics

- 2 measurement channels

- Robust design

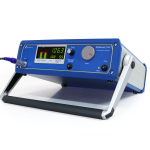

Rollscan 350 is a full-featured, self-contained unit which is portable for on-site measurements while also providing advanced capabilities for in-line and laboratory use.

- Measurement parameters adjustable via graphic user interface and front panel controls – No PC necessary

- Oscilloscope display with sensor feedback for real-time measurement diagnostics

- User interface in several languages

Rollscan 320 is a compact unit with low power consumption. It is designed for deployment in automated systems and production environments.

- A DIN rail mount attached to the backside of the unit

- Can be placed in electric cabinet

- 2 measurement channels, with 8 parallel analyzers up to 16 channels

Sensors

Stresstech provides a comprehensive range of Barkhausen noise sensors to suit different geometries and surface conditions. Sensors are available as contact or non‑contact types and can be used in manual, semi‑automated and automated systems.Key categories include:

- Camshaft Sensors: Adaptable sensors designed for the outer diameters of camshafts. Adjustable diameters and contact angles ensure precise detection across different lobes and journals.

- Pick-Up Sensors: Designed for plug taps, drill bits, and bearing surfaces. Ideal for measuring complex shapes and confined areas. Require an external magnetizing unit and feature changeable pole pieces for various diameters.

- Handheld Gear Sensors: Compact handheld probes for inspecting gear flanks and root radii (minimum radius 0.5 mm). Perfect for manual inspection tasks.

- Gear Sensors for GearScan and RoboScan: Automated sensors integrated into GearScan 500 and RoboScan systems to inspect gear flanks and root radii in production environments.

- Gear 3D CMM Sensors: Specialized sensors for use with coordinate measuring machines (CMMs) to collect Barkhausen noise data on gear flanks and roots during 3D inspection.

- OD Sensors: Designed for outer diameter and groove surface inspection on shafts, including landing gear and similar components.

- Flat Sensors: Available in narrow and high-power versions for flat or limited-access surfaces, ensuring uniform magnetic field distribution.

- General Purpose Sensors: Versatile sensors for a wide range of surface types. Changeable pole pieces allow easy adjustment of contact geometry.

- ID Sensors: Self-aligning sensors for internal diameter inspection, suitable for pipes, bores, and cylindrical cavities.

- Crankshaft Sensors: Designed for measuring outer diameter, radius, and face surfaces of crankshafts and similar rotating components.

Software

Barkhausen systems are powered by intuitive software platforms that enable data acquisition, analysis and automated measurement programming:

- ViewScan: Data acquisition software for collecting and analysing Rollscan measurement data. ViewScan includes optional extensions for material analysis, creating automated measurement programs and production database integration.

- MicroScan: A software that enables signal analysis of Barkhausen noise data. It provides a wide range of user definable measurement and analysis parameters, allowing the system to adjust to test conditions:

- Evaluate Barkhausen noise signal data using several functions and parameters. This can be used e.g. for residual stress and microstructure analysis.

- Gain deeper information about the phenomena.

- Analyze different parameters after the measurement.

- Compare multiple data sets at the same time. You have versatile options available for handling the data.